Synopsis

Synopsis

0

JDMF

0

EU WC

0

KDMF

0

NDC API

0

VMF

0

EDQM

0

USP

0

JP

0

Others

0

FDA Orange Book

0

Australia

0

South Africa

DRUG PRODUCT COMPOSITIONS

0

US Patents

0

US Exclusivities

0

Health Canada Patents

US Medicaid

NA

Annual Reports

NA

Regulatory FDF Prices

NA

0

FDF

0

Stock Recap #PipelineProspector

0

Weekly News Recap #Phispers

1. Alcohol, Polyvinyl

2. Liquifilm Tears

3. Polyviol

4. Tears, Liquifilm

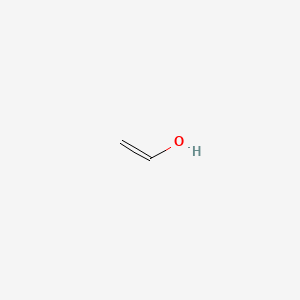

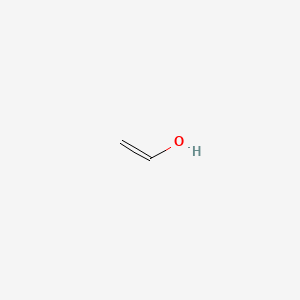

1. Ethenol

2. Vinyl Alcohol

3. 9002-89-5

4. Hydroxyethene

5. Hydroxyethylene

6. Gohsenol

7. Polyviol

8. Elvanol

9. Mowiol

10. 557-75-5

11. Ethenol, Homopolymer

12. Poly(vinyl Alcohol)

13. Poval

14. Alcotex 17f-h

15. Alkotex

16. Gelvatol

17. Rhodoviol

18. Einecs 209-183-3

19. Vinylalcohol

20. E1203

21. Polydesis

22. Polyvinol

23. Vinalak

24. Vinarol

25. Vinarole

26. Alvyl

27. Covol

28. Lemol

29. Mfcd00081922

30. Gohsenol Gh

31. Lamephil Oj

32. Sloviol R

33. Kuralon Vp

34. Vinacol Mh

35. Vinarol Dt

36. Vinarol St

37. Aracet Apv

38. Enbra Ov

39. Gtohsenol Gl 05

40. Polysizer 173

41. Cipoviol W 72

42. Gohsenol Ah 22

43. Gohsenol Gh 17

44. Gohsenol Gh 20

45. Gohsenol Gh 23

46. Gohsenol Gl 03

47. Gohsenol Gl 05

48. Gohsenol Gl 08

49. Gohsenol Gm 14

50. Gohsenol Gm 14l

51. Gohsenol Gm 94

52. Gohsenol Kh 17

53. Gohsenol Mg 14

54. Gohsenol Nh 05

55. Gohsenol Nh 17

56. Gohsenol Nh 18

57. Gohsenol Nh 20

58. Gohsenol Nh 26

59. Gohsenol Nl 05

60. Gohsenol Nm 14

61. Vinavilol 2-98

62. Elvanol T 25

63. Gosenol Kh-17

64. Sumitex H 10

65. Gelvatol 1-30

66. Gelvatol 1-60

67. Gelvatol 1-90

68. Gelvatol 2060

69. Gelvatol 2090

70. Gelvatol 3-91

71. Gohsenol N 300

72. Gohsenol Nm 114

73. Kurare Poval 120

74. Kurare 217

75. Rhodoviol 4/125

76. Elvanol 5105

77. Gelvatol 20-30

78. Kurare Pva 205

79. Rhodoviol 4-125p

80. Kurare Poval 1700

81. Lemol Gf-60

82. Poval 205s

83. Poval 217s

84. Poval C 17

85. Elvanol 51-05g

86. Elvanol 52-22g

87. Elvanol 73125g

88. Alcotex 88/05

89. Alcotex 88/10

90. Alcotex 99/10

91. Covol 971

92. Elvanol 50-42

93. Elvanol 52-22

94. Elvanol 70-05

95. Elvanol 71-30

96. Elvanol 90-50

97. Mowiol 4-88

98. Poval 117

99. Poval 120

100. Poval 203

101. Poval 205

102. Poval 217

103. Poval 420

104. Rhodoviol 16/200

105. Vinyl Alcohol, Polymers

106. Elvanol 522-22

107. Mowiol 26-88

108. Polyviol W 28/20

109. Rhodoviol R 16/20

110. Lemol 5-88

111. Lemol 5-98

112. Poval 1700

113. Polyviol Mo 5/140

114. Mowiol N 30-88

115. Mowiol N 50-98

116. Mowiol N 50/88

117. Mowiol N 70-98

118. Lemol 12-88

119. Lemol 16-98

120. Lemol 24-98

121. Lemol 30-98

122. Lemol 51-98

123. Lemol 60-98

124. Lemol 75-98

125. Polyviol M 13/140

126. Polyviol W 25/140

127. Polyviol W 40/140

128. Glo 5

129. Pvs 4

130. Polyvinylalcohol

131. Vinol

132. Pva 008

133. Gh 20

134. Gl 02

135. Gl 03

136. Gm 14

137. Nh 18

138. Nm 11

139. Nm 14

140. Pval 45/02

141. Pval 55/12

142. Gohsenol Nl05

143. Warcopolymer A 20

144. Ep 160

145. Vinyl Alcohol Polymer

146. Fh 1500

147. Vinylon Film 2000

148. Vinylon Film 3000

149. Vinol 125

150. Vinol 205

151. Vinol 351

152. Vinol 523

153. Ch2=choh

154. Polyvinylacetate, Hydrolyzed

155. M 13/20

156. Vinylon Film Vf-a 2500

157. Chembl76101

158. Dtxsid8051467

159. Bdbm50473787

160. Nsc108129

161. Vpb 105-2

162. Akos006229012

163. Nsc-108129

164. Ds-002731

165. Ft-0688082

166. Poly(vinyl Alcohol) (fully Hydrolyzed-low M.wt.)

167. Q409591

168. Q27120718

169. Polyvinyl Alcohol, 86-89% Hydrolyzed, Low Molecular Weight

170. Polyvinyl Alcohol, 98-99% Hydrolyzed, Low Molecular Weight

171. Polyvinyl Alcohol, 86-89% Hydrolyzed, Medium Molecular Weight

172. Polyvinyl Alcohol, 87-89% Hydrolyzed, High Molecular Weight

173. Polyvinyl Alcohol, 98-99% Hydrolyzed, High Molecular Weight

174. Polyvinyl Alcohol, 98-99% Hydrolyzed, Medium Molecular Weight

175. Poly(vinyl Alcohol) (fully Hydrolyzed-very Low M.wt.) Mw 7.000-10.000

176. Poly(vinyl Alcohol) N=2,000, (degree Of Saponification Ca. 80mol%)

| Molecular Weight | 44.05 g/mol |

|---|---|

| Molecular Formula | C2H4O |

| XLogP3 | 0.5 |

| Hydrogen Bond Donor Count | 1 |

| Hydrogen Bond Acceptor Count | 1 |

| Rotatable Bond Count | 0 |

| Exact Mass | 44.026214747 g/mol |

| Monoisotopic Mass | 44.026214747 g/mol |

| Topological Polar Surface Area | 20.2 Ų |

| Heavy Atom Count | 3 |

| Formal Charge | 0 |

| Complexity | 10.3 |

| Isotope Atom Count | 0 |

| Defined Atom Stereocenter Count | 0 |

| Undefined Atom Stereocenter Count | 0 |

| Defined Bond Stereocenter Count | 0 |

| Undefined Bond Stereocenter Count | 0 |

| Covalently Bonded Unit Count | 1 |

For use as a lubricant to prevent further irritation or to relieve dryness of the eye(s).

NIH; DailyMed. Current Medication Information for ARTIFICIAL TEARS- polyvinyl alcohol solution/ drops (Revised: June 2015). Available from, as of November 23, 2015: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=2ef16864-97cb-4dfe-9461-cba156144c69

Do not use if imprinted seal on the bottle neck is broken or missing. Do not use if solution changes color or becomes cloudy. To avoid contamination, do not touch tip of container to any surface. Replace cap after using.

NIH; DailyMed. Current Medication Information for ARTIFICIAL TEARS- polyvinyl alcohol solution/ drops (Revised: June 2015). Available from, as of November 23, 2015: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=2ef16864-97cb-4dfe-9461-cba156144c69

Stop use and ask a doctor if condition persists or increases discontinue use and consult a veterinarian.

NIH; DailyMed. Current Medication Information for ARTIFICIAL TEARS- polyvinyl alcohol solution/ drops (Revised: June 2015). Available from, as of November 23, 2015: https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=2ef16864-97cb-4dfe-9461-cba156144c69

For use as a lubricant to prevent further irritation or to relieve dryness of the eye(s).

Temporarily relieves burning and irritation due to dryness of the eye or from exposure to wind or sun. Lubricates the eyes and helps protect against further eye irritation/dryness.

Absorption

Polyvinyl alcohol is poorly absorbed from gastrointestinal tract, and readily eliminated from the body.

Volume of Distribution

This drug does not accumulate in the body when administered orally.

The fate of poly(vinyl alcohol) (PVA, 195,000 g/mol) was studied in rabbits and nude mice after intraperitoneal (i.p.) administration. In-vivo fluorescence imaging using nude mice allowed for studies of tetramethylrhodamine labeled PVA distribution in the body and tracking the urinary excretion. The excreted PVA was studied in detail after collecting the urine of rabbits over a time period of 28 days. The PVA was separated from the urine by dialysis and analyzed by FTIR spectroscopy, (1)H-NMR spectroscopy, and size exclusion chromatography (SEC). Even after extensive dialysis, it was found that the excreted PVA showed a characteristic brownish color. The spectroscopic techniques revealed that this color was caused by the urine pigment (a metabolite of bilirubin) that could not be separated completely from the PVA. SEC showed unambiguously that the PVA with the very high molar mass had a glomerular permeability in the kidneys. Simultaneously, histological studies of the kidneys and the liver demonstrated that the tissues did not show any obvious damage.

PMID:20119945 Jiang Y et al; J Biomed Mater Res B Appl Biomater 93 (1): 275-84 (2010)

Polyvinyl alcohol (PVA) is a polymer with a wide range of molecular weights and uses. Recently, low molecular weight formulations of PVA have been used as components of contraceptive products designed for intravaginal administration in human females. Previous studies in animals have determined that little or no absorption of PVA occurs from the gastrointestinal (GI) tract. However, there is some concern that PVA of lower molecular weights might be absorbed across membranes of the reproductive tract. Consequently, this work has investigated the absorption of low molecular weight PVA across biological membranes of the reproductive and GI tracts of Fischer 344 rats. Oral administration of ten consecutive daily doses of (14)C PVA resulted in little apparent absorption of the dose from the GI tract. In contrast, intravaginal administration of (14)C PVA resulted in increasing concentrations of PVA-derived radioactivity in major tissues following one, three or ten daily doses of the estimated human dose of 3 mg/kg. PVA-derived radioactivity was concentrated mainly in the liver, reaching a peak greater than 1750 ng equivalents/g tissue 24 hours following ten daily doses. Over 300 ng equivalents/g tissue were still present in the liver 30 days following the last dose.

PMID:2340195 Sanders JM, Matthews HB; Hum Exp Toxicol 9 (2): 71-7 (1990)

/Researchers/ report on the distribution of PVA of low (mol. wt 37,000), medium (mol. wt 133,000) and high (mol. wt 195,000) grades following 4 weeks of daily subcutaneous injection of 1 mL of 5% solutions to female Holtzman rats. Polymers of medium and high molecular weights were found in the tissues of the adrenal medulla, spleen, myocardium, liver and kidney. Low molecular weight polymers were not found in any tissues.

DeMerlis CC, Schoneker DR; Food Chem Toxicol 41 (3): 319-26 (2003)

PVA sponges (Ivalon) implanted into guinea pigs or rats appeared to disintegrate or deform, suggestive of phagocytosis by macrophages and giant cells or resorption, but there was no indication of the ultimate fate of the sponges or the cellular PVA. Therefore it would seem that while subcutaneously injected PVA may undergo bioaccumulation and implanted PVA undergo partial resorption, intravenous or orally administered PVA is quickly eliminated.

DeMerlis CC, Schoneker DR; Food Chem Toxicol 41 (3): 319-26 (2003)

For more Absorption, Distribution and Excretion (Complete) data for POLYVINYL ALCOHOL (7 total), please visit the HSDB record page.

When injected intravenously, polyvinyl alcohol has a half-life of 90 min. Intraocularly, in eye drop form, the half-life is 7.2 minutes.

As a synthetic resin with hydrophilic properties, it increases the persistence of tear film and therefore lubricates and soothes dry/irritated eyes.

Related Excipient Companies

Dosage Form : Softgel Capsule

Grade : Not Available

Application : Solubilizers

Excipient Details : Nonionic solubilizer, emulsifier and co-emulsifier

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]

FULL SCREEN VIEW Click here to open all results in a new tab [this preview display 10 results]Excipients by Applications

Market Place

ABOUT THIS PAGE

88

PharmaCompass offers a list of Polyvinyl Alcohol API API manufacturers, exporters & distributors, which can be sorted by GMP, USDMF, JDMF, KDMF, CEP (COS), WC, Price,and more, enabling you to easily find the right Polyvinyl Alcohol API manufacturer or Polyvinyl Alcohol API supplier for your needs.

Send us enquiries for free, and we will assist you in establishing a direct connection with your preferred Polyvinyl Alcohol API manufacturer or Polyvinyl Alcohol API supplier.

PharmaCompass also assists you with knowing the Polyvinyl Alcohol API API Price utilized in the formulation of products. Polyvinyl Alcohol API API Price is not always fixed or binding as the Polyvinyl Alcohol API Price is obtained through a variety of data sources. The Polyvinyl Alcohol API Price can also vary due to multiple factors, including market conditions, regulatory modifications, or negotiated pricing deals.

A Polyvinyl Alcohol API manufacturer is defined as any person or entity involved in the manufacture, preparation, processing, compounding or propagation of Polyvinyl Alcohol API, including repackagers and relabelers. The FDA regulates Polyvinyl Alcohol API manufacturers to ensure that their products comply with relevant laws and regulations and are safe and effective to use. Polyvinyl Alcohol API API Manufacturers are required to adhere to Good Manufacturing Practices (GMP) to ensure that their products are consistently manufactured to meet established quality criteria.

click here to find a list of Polyvinyl Alcohol API manufacturers with USDMF, JDMF, KDMF, CEP, GMP, COA and API Price related information on PhamaCompass.

A Polyvinyl Alcohol API supplier is an individual or a company that provides Polyvinyl Alcohol API active pharmaceutical ingredient (API) or Polyvinyl Alcohol API finished formulations upon request. The Polyvinyl Alcohol API suppliers may include Polyvinyl Alcohol API API manufacturers, exporters, distributors and traders.

click here to find a list of Polyvinyl Alcohol API suppliers with USDMF, JDMF, KDMF, CEP, GMP, COA and API Price related information on PharmaCompass.

A Polyvinyl Alcohol API DMF (Drug Master File) is a document detailing the whole manufacturing process of Polyvinyl Alcohol API active pharmaceutical ingredient (API) in detail. Different forms of Polyvinyl Alcohol API DMFs exist exist since differing nations have different regulations, such as Polyvinyl Alcohol API USDMF, ASMF (EDMF), JDMF, CDMF, etc.

A Polyvinyl Alcohol API DMF submitted to regulatory agencies in the US is known as a USDMF. Polyvinyl Alcohol API USDMF includes data on Polyvinyl Alcohol API's chemical properties, information on the facilities and procedures used, and details about packaging and storage. The Polyvinyl Alcohol API USDMF is kept confidential to protect the manufacturer’s intellectual property.

click here to find a list of Polyvinyl Alcohol API suppliers with USDMF on PharmaCompass.

A Polyvinyl Alcohol API CEP of the European Pharmacopoeia monograph is often referred to as a Polyvinyl Alcohol API Certificate of Suitability (COS). The purpose of a Polyvinyl Alcohol API CEP is to show that the European Pharmacopoeia monograph adequately controls the purity of Polyvinyl Alcohol API EP produced by a given manufacturer. Suppliers of raw materials can prove the suitability of Polyvinyl Alcohol API to their clients by showing that a Polyvinyl Alcohol API CEP has been issued for it. The manufacturer submits a Polyvinyl Alcohol API CEP (COS) as part of the market authorization procedure, and it takes on the role of a Polyvinyl Alcohol API CEP holder for the record. Additionally, the data presented in the Polyvinyl Alcohol API CEP (COS) is managed confidentially and offers a centralized system acknowledged by numerous nations, exactly like the Polyvinyl Alcohol API DMF.

A Polyvinyl Alcohol API CEP (COS) is recognised by all 36 nations that make up the European Pharmacopoeia Convention. Polyvinyl Alcohol API CEPs may be accepted in nations that are not members of the Ph. Eur. at the discretion of the authorities there.

click here to find a list of Polyvinyl Alcohol API suppliers with CEP (COS) on PharmaCompass.

Polyvinyl Alcohol API Active pharmaceutical ingredient (API) is produced in GMP-certified manufacturing facility.

GMP stands for Good Manufacturing Practices, which is a system used in the pharmaceutical industry to make sure that goods are regularly produced and monitored in accordance with quality standards. The FDA’s current Good Manufacturing Practices requirements are referred to as cGMP or current GMP which indicates that the company follows the most recent GMP specifications. The World Health Organization (WHO) has its own set of GMP guidelines, called the WHO GMP. Different countries can also set their own guidelines for GMP like China (Chinese GMP) or the EU (EU GMP).

PharmaCompass offers a list of Polyvinyl Alcohol API GMP manufacturers, exporters & distributors, which can be sorted by USDMF, JDMF, KDMF, CEP (COS), WC, API price, and more, enabling you to easily find the right Polyvinyl Alcohol API GMP manufacturer or Polyvinyl Alcohol API GMP API supplier for your needs.

A Polyvinyl Alcohol API CoA (Certificate of Analysis) is a formal document that attests to Polyvinyl Alcohol API's compliance with Polyvinyl Alcohol API specifications and serves as a tool for batch-level quality control.

Polyvinyl Alcohol API CoA mostly includes findings from lab analyses of a specific batch. For each Polyvinyl Alcohol API CoA document that a company creates, the USFDA specifies specific requirements, such as supplier information, material identification, transportation data, evidence of conformity and signature data.

Polyvinyl Alcohol API may be tested according to a variety of international standards, such as European Pharmacopoeia (Polyvinyl Alcohol API EP), Polyvinyl Alcohol API JP (Japanese Pharmacopeia) and the US Pharmacopoeia (Polyvinyl Alcohol API USP).